Durable construction

Casing of Amrta fan coil units shall be galvanized steel panel. And the condensate pan is treated by extruded seamless technology to prevent the leakage. Fire rated thermal insulation is attached to the condensate pan integrally. Construction of the units is sturdy and permanent.

High efficiency

Coils shall be fabricated by Φ9.25mm cooper tubes and hydrophilic aluminum fins. Tubes are expanded into the fins accurately to confirm the heat transfer efficiency. Fans shall be high airflow rate and low noise design. And brass headers of copper tubes well distribute water flow configuration to assure optimum heat transfer efficiency.

Low noise and operating cost

Fans shall be specially designed with over-sized galvanized multi-blade centrifugal wheel, operating with low noise, high static pressure and airflow rate. And hi-static, permanent split capacitor motors shall be factory balance tested for proof the high efficiency and quite operation.

Easy maintenance

Motors shall be fabricated with rolling bearing and quenched and tempered steel shaft with antirust treated. Three-speed or LCD thermostat is convenient to control the airflow and room temperature.

Low installation cost

Units shall be low-weight design. Drain pipes and wires are easy for connection. The water connection direction and air return are changeable according to the site requirements.

Specification

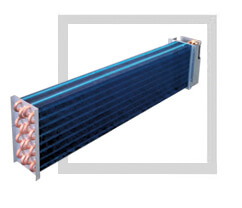

Coil: high efficiency heat transfer performance

Coils shall be manufactured by Φ9.25mm cooper tubes and sine-wave hydrophilic aluminum fins. Copper tubes are mechanically expanded to bond with aluminum fins. Considering water flow configuration and the performance of heat transfer, headers shall be fabricated of brass material.

Casing: reliable structure and elegant design

Casing shall be constructed by extruded galvanize steel panel (class 1), fitting for sturdy command.

Drain pan: special design for no leakage

Condensate drain pans shall be fabricated by high quality panel with punch forming and hot-dip baking paint treated. PE insulation with thickness of 7 mm is designed to tightly bond with drain pan with the benefit of easy manufacturing, anti-leakage and elegant feature eventually extending the drain pan life.

Motor: high efficiency and low power consumption

Motors shall consist of low noise permanent capacitor motors and total hermetic rolling bearing with permanent lubricated. The base of motor shall be isolated by rubber mount to minimize the vibration and operation noise.

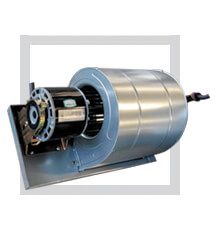

Fans: low acoustic level

Fans shall be equipped with efficient, low noise, multi-blade centrifugal fan with oversized fan wheel, and shall be manufactured with galvanized steel panel for well dynamic balance performance.

Controller: facile and comfortable

Controller shall be facile with changeable speed of fans and friendly interface for users. AMT801 controller is used as optional allowing users to select operating mode and fan speed manually, to set the temperature by using the knob. Or AMT806 Series Thermostats is advanced control as optional using digital LCD display and EL Backlight, allowing users: to detect the room temperature with NTC sensor and compares it with the set-point for automatically keeping the room temperature stable; to adjust automatically 3-speed of fan; to save data and memory with output reliable by relay.

Options

![]() Electric heater

Electric heater ![]() Removable aluminum filter

Removable aluminum filter

![]() High static pressure fan

High static pressure fan ![]() Stainless steel condensate pan

Stainless steel condensate pan

![]() Air return box (below return or back return)

Air return box (below return or back return) ![]() Controller: AMT801 controller

Controller: AMT801 controller

![]() Fresh air inlet for air return box or AMT806 Series Thermostats

Fresh air inlet for air return box or AMT806 Series Thermostats

Advanced Option (Upgraded EC Fan Coil Unit)

Symbolizing by outstanding energy-saving effect, the EC fan coil unit saves more than 30% energy compared with traditional fan coil units at the same motor speed. When the fan motor operates at mid or low speed, the effect of energy-saving is more remarkable.

Intelligent control by standard smart thermostat, with microprocessor technology, effectively permits to achieve the stepless speed variation with automatic adjustment of motor charges and electrical dampers by detecting the ambient temperature and the set-point, significantly improve energy-saving, comfort and reliability.

Traditional fan coil unit is normally operating in 3-variable-speed with a range of ±2oC for room temperature fluctuation. The upgraded EC fan coil unit features continuous automatic adjustment technology and stepless speed variation, which controls the room temperature fluctuation under ±0.5oC.

Operating with small vibration and any electromagnetic noise ensures a quiet operation and improves the tranquility and comfort for room environment.

Using electronic commutation module, reducing the abrasion of electrical components, makes EC fan coil units with higher quality and longer life than traditional AC motor fan coil units.

| Model | 34WA | 51WA | 68WA | 85WA | 102WA | 136WA | 170WA | 204WA | 238WA | ||

| Rated air volume m³/h | H | 340 | 510 | 680 | 850 | 1020 | 1360 | 1700 | 2040 | 2380 | |

| M | 255 | 383 | 510 | 638 | 765 | 1020 | 1275 | 1530 | 1785 | ||

| L | 170 | 255 | 340 | 425 | 510 | 680 | 850 | 1020 | 1190 | ||

| Rated cooling capacity W | H | 1800 | 2700 | 3600 | 4500 | 5400 | 7200 | 9000 | 10800 | 12600 | |

| M | 1440 | 2160 | 2880 | 3600 | 4320 | 5760 | 7200 | 8640 | 10080 | ||

| L | 1170 | 1755 | 2340 | 2925 | 3510 | 4680 | 5850 | 7020 | 8190 | ||

| Rated heating capacity W | H | 2700 | 4050 | 5400 | 6750 | 8100 | 10800 | 13500 | 16200 | 18900 | |

| M | 2160 | 3240 | 4320 | 5400 | 6480 | 8640 | 10800 | 12960 | 15120 | ||

| L | 1755 | 2633 | 3510 | 4388 | 5265 | 7020 | 8775 | 10530 | 12285 | ||

| Input power W | 12Pa | H | 37 | 52 | 62 | 76 | 86 | 134 | 152 | 189 | 228 |

| 30Pa | H | 44 | 59 | 72 | 87 | 100 | 156 | 174 | 212 | 253 | |

| 50Pa | H | 49 | 66 | 84 | 100 | 108 | 174 | 210 | 250 | 300 | |

| Noise dB(A) | 12Pa | H | 37 | 39 | 41 | 43 | 45 | 46 | 48 | 50 | 52 |

| 30Pa | H | 40 | 42 | 44 | 46 | 47 | 48 | 50 | 52 | 54 | |

| 50Pa | H | 42 | 44 | 46 | 47 | 49 | 50 | 52 | 54 | 56 | |

| Water volume kg/h | 390 | 550 | 700 | 820 | 910 | 1340 | 1590 | 1800 | 2070 | ||

| Water pressure loss kPa | ≤30 | ≤30 | ≤30 | ≤30 | ≤40 | ≤40 | ≤40 | ≤40 | ≤50 | ||

| Weight kg | Without plenum box | 12.5 | 14 | 14 | 15.5 | 16.5 | 22.5 | 30 | 33 | 33.5 | |

| With plenum box | 14.5 | 16 | 17 | 19.5 | 20.5 | 27.5 | 35 | 38 | 39.5 | ||

| Motor | Type | E class insulation, permanent capacitor, 3 speed fan | |||||||||

| Qty | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 3 | ||

| Fan | Type | Double inlet, forward curve, multi blades, centrifugal fan | |||||||||

| Type | 1 | 2 | 2 | 2 | 2 | 3 | 4 | 4 | 4 | ||

| Water connection pipe | 3/4” (DN20) | ||||||||||

| Condensed water pipe | 3/4” (DN20) | ||||||||||

| Max working pressure | 1.6MPa | ||||||||||

| Power supply | AC 220V/50Hz | ||||||||||

Note:

1. Cooling capacity is based on air inlet temperature 27oC DB/19.5oC WB, entering water temperature 7oC, T5oC.

2. Heating capacity is based on air inlet temperature 21oC, entering water temperature 60oC, air flow volume and water flow rate are the same with cooling mode.

3. MPT-Mole pipe thread, FPT-Female pipe thread.

4. ESP for C and F series is 0Pa.

5. For FVE, FVC series, there is no Model 140; the performance parameters of FVE and FVC are the same with FHC.

6. Specifications in this catalog are subject to change without notice.

* Please leave your message!We will send detail technical info and quotation to you!